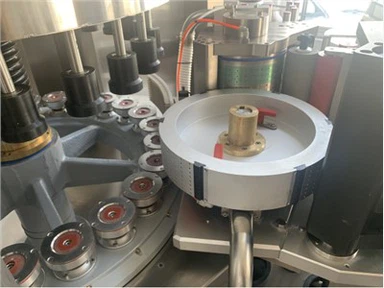

20 Liter Water Bottle Filling Machine

The 20 Liter Water Bottle Filling Machine is a state-of-the-art device designed to streamline the process of filling large water bottles with ease and efficiency. This machine is specifically designed to cater to the needs of businesses that require large quantities of purified water to meet their daily operational requirements.

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Filling machines will be prepared according to the customer's needs and can be suitable for many types of products – milk & dairy products (fresh milk, ESL with 21-28 days shelf-life or aseptic). We can also manufacture capping machines for almost every type of cap and labeling machines (for self-adhesive, sleeve or hot-melt OPP label).

We are proud to offer our clients a wide variety of different water bottling equipment. We offer everything you need for a water bottle filling machine line. Our bottle filling equipment is manufactured to the strictest quality standards in sanitary conditions that ensure we deliver the best possible products to our valued customers. The bottle filling equipment we offer our clients is ideal for filling a variety of liquids from water thin to highly viscous products. Call for a quote no matter your packaging challenges.

Equipment Structure

PREFORM FEEDING

HEATING OVEN

BLOWING STATION

BOTTLE OUT

BLOWING FILLING CAPPING

Cooperation brand

WAHAHA

XIWANG

DAO DAO QUAN

CHIVALRY

JINMAILANG

NONGFU SPRING

Finding the Best Liquid Filling Systems for Your Needs

Product Viscosity

The thickness or thinness of your product, determined by its viscosity, plays a crucial role in the selection of a filling system. Low-viscosity liquids like water or light juices can be filled using simpler systems, while high-viscosity products, such as thick pastes or oils, may require more specialized fillers equipped to handle viscous liquids.

01

Bottle Type

The shape, size, and material of your bottles matter when choosing a filler. Some filling systems are better suited for specific bottle types, such as small bottles, large containers, or unusually shaped vessels. The filler you choose must be able to accommodate the bottle type and ensure accurate, clean filling.

02

Required Fill Rate

Your production throughput needs dictate the speed at which your liquid filler must operate. High-speed production lines require filling systems capable of matching the line's pace to avoid bottlenecks and maximize efficiency.

03

Specific Fill Volume

The precise amount of product that needs to be dispensed into each container should be considered. Some filling systems offer more accuracy than others, especially important for products where consistent dosing is critical.

04

Metering or Filling System

There are various types of filling systems, including time gravity, piston filling, overflow filling, and pressure filling, among others. Each system has its advantages and is suited to specific product types and viscosities. For example, piston fillers are often used for thick or viscous liquids because they can provide a consistent volume with each stroke.

05

Hot Tags: 20 liter water bottle filling machine, China 20 liter water bottle filling machine manufacturers, suppliers, factory, Bottled Water Filling Machine, 5 Gallon Water Bottle Filling Machine, 5 Liter Water Bottle Filling Machine, , 12 Liter Water Bottle Filling Machine, 15 Liter Water Bottle Filling Machine