What is a blow-fill-cap all-in-one machine?

May 26, 2025

The blow-fill-cap all-in-one machine is an integrated system that integrates bottle blowing, filling and capping solutions. It reduces the intermediate links such as conveying, empty bottle handling, stacking and storage processes, improves packaging hygiene conditions, reduces cross contamination, improves overall operating efficiency, and significantly reduces energy consumption, thereby reducing the comprehensive production cost of beverage production companies.

The production capacity ranges from 12,000 bottles/hour to 80,000 bottles/hour. The blow-tube selection all-in-one machine is suitable for pure water, carbonated beverages, juice, tea, liquid milk, liquid condiments and daily chemical products packaged in PET bottles.

Analysis and comparison of the technical characteristics of the blow-fill-cap all-in-one machine and traditional filling machines.

1. Stable infrared heating system and independent heat balance adjustment device make the temperature of the preform consistent when heating, and the process has good consistency and stability, further improving the yield rate.

2. Specially designed secondary blowing system monitors the pressure change curve of each cavity during the bottle molding process in real time, providing timely and accurate real-time parameters for process adjustment, greatly facilitating operators to adjust process parameters, while ensuring stable bottle molding quality.

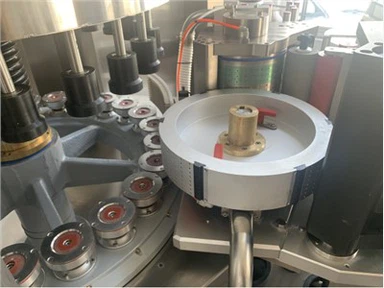

3. High-speed and high-precision diaphragm filling valve: It is equipped with a return air channel independent of the liquid cylinder. The air displaced in the PET bottle does not enter the liquid cylinder during the filling process to avoid secondary pollution; it is equipped with a cleaning cup to achieve online CIP cleaning.

4. Sanitary washable capping machine: The kinematically optimized cam surface design ensures that the impact force of the capping machine is minimized; the bottle bottom support plate of the bottle discharge wheel adopts a spiral descending method, and the bottle shape does not need to be adjusted without adjusting the height of the bottle discharge conveyor chain.