Bottle filling machine operator training guide

Feb 18, 2025

The training of bottle filling machine operators is essential to ensure the normal operation and production efficiency of the equipment. Based on the search results provided, we can compile a detailed bottle filling machine operator training guide.

1. Equipment preparation

- Confirm the power supply: Make sure that the equipment is connected to the power supply and the power supply voltage meets the equipment requirements.

- Check the equipment: Check whether there are any abnormalities on the outside of the equipment, such as whether the equipment is deformed, whether the connecting parts are loose, whether the power cord is worn or aged, etc.

- Confirm the bottle cap specifications: Make sure that the bottle caps to be used meet the equipment specifications.

- Check the control panel: Open the equipment control panel and confirm whether the status of each button and indicator light is normal.

2. Operation steps

- Place the bottle: Place the bottle to be used at the bottle feed port, pay attention to the bottle mouth facing up, and then press the start button.

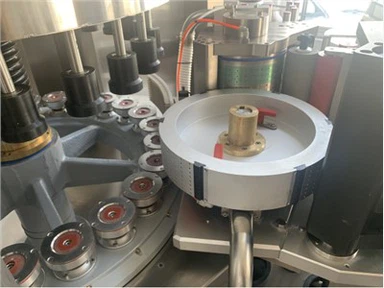

- Take the bottle cap: The bottle enters the bottle cap sealing area, and the robot arm takes a bottle cap from the bottle cap storage bin and places it above the bottle mouth.

- Sealing operation: The bottle cap sealing head moves downward and starts to rotate when it contacts the bottle until the bottle cap is completely locked.

- Remove the sealing head: Remove the sealing head to complete the sealing operation of a bottle.

- Repeat the operation: Repeat the above steps to seal multiple bottles at a time.

- Job completion: After the job is completed, turn off the power and clean the equipment and work area.

3. Troubleshooting

- No response: There is no response when the bottle enters the equipment. Check whether the power is on, whether the equipment is connected correctly, and whether the indicator light on the equipment control panel is on.

- Bottle cap is unstable: The bottle cap is unstable or cannot be embedded in the bottle. Check whether the bottle cap is clean. If there is dirt, please clean the bottle cap; whether the bottle cap is damaged. If there is damage, please replace the bottle cap.

- Bottle cap is not secure: The bottle cap is not secure after the bottle is sealed. Check whether the bottle cap is tight. If it is loose, please check whether the bottle diameter meets the bottle cap specifications to ensure that the bottle cap and the bottle are well matched; the bottle cap pressure can be appropriately increased.

- Other faults: If other faults cannot be solved, please contact the professional maintenance personnel of the equipment to avoid disassembling and repairing the equipment by yourself.

4. Safety operating procedures

- Prohibition of illegal operations: It is prohibited to perform illegal operations such as cleaning and maintenance while the equipment is running.

- Wear protective equipment: Wear protective equipment that meets the regulations, such as safety helmets, protective glasses, gloves, etc.

- Familiar with the emergency stop button: Familiar with the location of the emergency stop button, master emergency treatment measures, and ensure the safety of personnel and equipment.

- Regular inspection: Regularly check the packaging machine equipment, electrical system, operating procedures, etc. to ensure the normal operation of the equipment.

5. Training assessment and feedback

- Training assessment: Establish a training assessment mechanism, evaluate and feedback the training effect of employees, and ensure the training effect.

- Case analysis: Through actual case analysis, deepen employees' understanding and awareness of safe operation of packaging machines.

- Regular retraining: Regularly retrain employees on safety knowledge to consolidate the training effect and improve employees' safety awareness.

6. Conclusion

Operators should memorize the above equipment preparation, operation steps, troubleshooting, etc., and be sure to carefully read the equipment manual and safety precautions before operating the equipment to avoid damage to personnel and equipment caused by improper use of the equipment.

Through this training guide, operators can better master the operation methods and safety regulations of the bottle filling machine, reduce the possibility of accidents, ensure their own safety, and improve production efficiency.